From Molecular Electronics to Proteonics: Break Junctions for Biomarker Detection

From Molecular Electronics to Proteonics: Break Junctions for Biomarker Detection

By Ehsan A. Q. Syed 1,2, Waseem Asghar 1,2, Joseph A. Billo 1,2, Azhar Ilyas 1,2, and Samir M. Iqbal 1,2,3 *

1Department of Electrical Engineering, 2Nanotechnology Research and Teaching Facility, 3Biomedical Engineering Program, University of Texas at Arlington and University of Texas Southwestern Medical Center at Dallas, University of Texas at Arlington, Arlington, TX, USA

*smiqbal@uta.edu

Break junctions have emerged as an important tool to interrogate electrical transport properties of molecules. A number of approaches have been reported for the fabrication of break junctions, including optical/e-beam lithography, electromigration, and electrochemical deposition of conductive materials. All of these are either time consuming (due to slow e-beam writing) or give low yield. We report a novel method to fabricate a nanogap between two gold electrodes. First a scratch is made using focused ion beam milling followed by electromigration. Most of the break junctions show negligible conductivity. Our method provides rapid and high throughput break junction fabrication. Break Junctions are used to selectively capture and electrically detect cancer biomarker protein.

The “Break Junctions” provide a way to interrogate electrical transport properties of molecules. Different process flows are employed for break junctions fabrication e.g. optical/e-beam lithography [1-3], electromigration [4, 5], mechanical control of suspended electrodes/strips [6, 7], electrochemical deposition of materials [8] and nanowires [9]. All approaches either suffer from time consuming e- beam writing of the whole device or low yield that results from stochastic nature of electromigration process. Here, we report an innovative and novel method of break junction fabrication with focused ion beam (FIB) “scratching” followed by electromigration. The approach results into elegant, rapid and controlled high-yield nano-manufacturing of break junctions at exact locations with very narrow distribution of the gaps (between electrodes). FIB is used to introduce defects in a lithographically defined metal line by scratching the line surface at specific location. The scratch results in high resistance at that particular scratched part and induced electromigration results in the break at that exact location. We have reproducibly fabricated gaps ranging between 100-200 nm. The break junctions are then functionalized with aptamer molecules and are used to detect an important cancer biomarker Epidermal Growth Factor Receptor (EGFR). EGFR over-expression is known in several types of cancers like breast cancer [10], lung cancer [11], cervical cancer [12], bladder cancer [13], esophageal cancer [14] and ovarian cancer [15].

METHOD

The process comprises two-step photolithography for 3 micron lines and probing (Fig 1). We used FIB “scratching” to remove a thin layer of metal from the lines. The novelty lies in using optical lithography to define the lines, and instead of low-throughput e-beam writing of the full electrode features, FIB writes a 50 nm wide scratch, reducing time to fabricate and increasing throughput.

ANALYSIS AND CONCLUSION

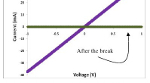

Current-Voltage (I-V) measurements of break junctions were done before and after FIB scratch, and after electromigration using Agilent 4155C Semiconductor Parameter Analyzer. Following the scratch, a ramping voltage was applied and a sudden drop was seen in the current, representing the complete break, and seen from complete loss of conductivity (Fig. 4). Once EGFR was selectively captured between the electrodes, two orders of magnitude increase in direct current (DC) was noticed.

A novel class of probe molecules, known as aptamers, are being used with this framework of break junctions for the specific detection of EGFR. The aptamers are essentially DNA or RNA molecules that are iteratively selected for their specific binding with nucleic acids, proteins, and small organic compounds. Apart from their natural exclusion against biofouling, aptamers can be chemically synthesized, and can be labeled/loaded with various reporters/payload. The aptamers are also stable at various salinity, temperature and surface functionalizations unlike antibody functionalization of devices. Anti-EGFR aptamers have been previously used for the isolation and enrichment of cancer cells [19]. In the current context, work is underway for the electrical detection of EGFR, selectively captured with surface-bound anti-EGFR aptamer. EGFR is a large, monomeric, modular glycoprotein [20] with its dimensions on the order of tens of angstroms (Fig. 5). It is expected that the protein structure would expand when it binds to the probe aptamer via its extracellular ligand binding domain. This provides a low demand on the break junction size stringency; we can detect proteins (biomarkers or others) even with the break junctions that are larger than just a few nanometers.

ACKNOWLEDGMENT

The authors would like to acknowledge useful discussions with Mohammed R. Noor and Priyanka P. Ramachandran. We thank Dr. Shawn Christensen for help with the crystal structure calculations and visualization of EGFR. We are also thankful to the staff at Nanotechnology Research and Teaching facility for their help and training at various stages of the presented work. Partial chip characterization was carried out at UTA Characterization Center for Materials and Biology (C2MB). This work is supported with a CAREER grant to S.M.I. from National Science Foundation vide ECCS-0845669.

To find out more about this topic, read the complete article, from the presentation at the IEEE/NIH 5th Annual Life Science Systems and Applications Workshop (LiSSA’11), 2011

- S. M. Luber, S. Strobel, H. P. Tranitz, W. Wegscheider, D. Schuh, and M. Tornow, “Nanometre spaced electrodes on a cleaved AlGaAs surface,” Nanotechnology, vol. 16, p. 1182, 2005.

- K. Liu, P. Avouris, J. Bucchignano, R. Martel, S. Sun, and J. Michl, “Simple fabrication scheme for sub-10 nm electrode gaps using electron-beam lithography,” Applied Physics Letters, vol. 80, pp. 865-867, 2002.

- F. Carcenac, L. Malaquin, and C. Vieu, “Fabrication of multiple nano-electrodes for molecular addressing using high-resolution electron beam lithography and their replication using soft imprint lithography,” Microelectronic Engineering, vol. 61, pp. 657-663, 2002.

- H. Park, A. K. L. Lim, A. P. Alivisatos, J. Park, and P. L. McEuen, “Fabrication of metallic electrodes with nanometer separation by electromigration,” Applied Physics Letters, vol. 75, p. 301, 1999.

- S. M. Iqbal, G. Balasundaram, S. Ghosh, D. E. Bergstrom, and R. Bashir, “Direct current electrical characterization of ds-DNA in nanogap junctions,” Applied Physics Letters, vol. 86, p. 153901, 2005.

- M. A. Reed, C. Zhou, C. J. Muller, T. P. Burgin, and J. M. Tour, “Conductance of a molecular junction,” Science, vol. 278, p. 252, 1997.

- C. Zhou, C. J. Muller, M. R. Deshpande, J. W. Sleight, and M. A. Reed, “Microfabrication of a mechanically controllable break junction in silicon,” Applied Physics Letters, vol. 67, p. 1160, 1995.

- A. Umeno and K. Hirakawa, “Fabrication of atomic-scale gold junctions by electrochemical plating using a common medical liquid,” Applied Physics Letters, vol. 86, p. 143103, 2005.

- L. T. Cai, H. Skulason, J. G. Kushmerick, S. K. Pollack, J. Naciri, R. Shashidhar, D. L. Allara, T. E. Mallouk, and T. S. Mayer, “Nanowire-based molecular monolayer junctions: synthesis, assembly, and electrical characterization,” J. Phys.

- Chem. B, vol. 108, pp. 2827-2832, 2004. J. G. Klijn, P. M. Berns, P. I. Schmitz, and J. A. Foekens, “The clinical significance of epidermal growth factor receptor (EGF- R) in human breast cancer: a review on 5232 patients,” Endocrine reviews, vol. 13, p. 3, 1992. T. J. Lynch, D. W. Bell, R. Sordella, S. Gurubhagavatula, R. A. Endocrine reviews, vol. 13, p. 3, 1992.

- T. J. Lynch, D. W. Bell, R. Sordella, S. Gurubhagavatula, R. A. Okimoto, B. W. Brannigan, P. L. Harris, S. M. Haserlat, J. G. Supko, and F. G. Haluska, “Activating mutations in the epidermal growth factor receptor underlying responsiveness of non-small-cell lung cancer to gefitinib.” vol. 350, 2004, pp. 2129-2139.

- A. M. F. Kersemaekers, G. J. Fleuren, G. G. Kenter, L. Van den Broek, S. M. Uljee, J. Hermans, and M. J. Van de Vijver, “Oncogene alterations in carcinomas of the uterine cervix: overexpression of the epidermal growth factor receptor is associated with poor prognosis,” Clinical Cancer Research, vol. 5, p. 577, 1999.

- K. Mellon, C. Wright, P. Kelly, C. H. W. Horne, and D. E. Neal, “Original Articles: Bladder Cancer: Long-Term Outcome Related to Epidermal Growth Factor Receptor Status in Bladder Cancer,” The Journal of urology, vol. 153, pp. 919-925, 1995.

- S. Inada, T. Koto, K. Futami, S. Arima, and A. Iwashita, “Evaluation of malignancy and the prognosis of esophageal cancer based on an immunohistochemical study (p53, E- cadherin, epidermal growth factor receptor),” Surgery today, vol. 29, pp. 493-503, 1999.

- J. Fischer-Colbrie, A. Witt, H. Heinzl, P. Speiser, K. Czerwenka, P. Sevelda, and R. Zeillinger, “EGFR and steroid receptors in ovarian carcinoma: comparison with prognostic parameters and outcome of patients,” Anticancer research, vol. 17, pp. 613-619, 1997.

- W. Asghar, P. P. Ramachandran, A. Adewumi, M. R. Noor, and S. M. Iqbal, “Rapid Nanomanufacturing of Metallic Break Junctions using Focused Ion Beam Scratching and Electromigration,” Journal of Manufacturing Science and Engineering, vol. 132, p. 030911, 2010.

- D. R. Strachan, D. E. Smith, D. E. Johnston, T. H. Park, M. J. Therien, D. A. Bonnell, and A. T. Johnson, “Controlled fabrication of nanogaps in ambient environment for molecular electronics,” Applied Physics Letters, vol. 86, p. 043109, 2005.

- P. P. Ramachandran, S. M. Christensen, and S. M. Iqbal, “Electronic detection of selective proteins using non antibody- based CMOS chip,” in IEEE-NIH Life Science Systems and Applications Workshop 2009 (LiSSA’09), Bethesda, MD, 2009, pp. 1-4.

- Y. Wan, Y.-t. Kim, N. Li, S. K. Cho, R. Bachoo, A. D. Ellington, and S. M. Iqbal, “Surface-Immobilized Aptamers for Cancer Cell Isolation and Microscopic Cytology,” Cancer Research, vol. 70, pp. 9371-9380, 2010.

- T. P. J. Garrett, N. M. McKern, M. Lou, T. C. Elleman, T. E. Adams, G. O. Lovrecz, H.-J. Zhu, F. Walker, M. J. Frenkel, P. A. Hoyne, R. N. Jorissen, E. C. Nice, A. W. Burgess, and C. W. Ward, “Crystal Structure of a Truncated Epidermal Growth Factor Receptor Extracellular Domain Bound to Transforming Growth Factor α,” Cell, vol. 110, pp. 763-773, 09/20 2002.